What Is Acetal Resin Material (POM Resin)?

Acetal resin, often referred to as POM resin (Polyoxymethylene resin) stands as a highly crystalline thermoplastic polymer known for its outstanding wear resistance, be it in wet or dry conditions. Prochase acetal resin suppliers offer high-quality materials for industrial use.

Homopolymers VS Copolymers from POM Resins

POM resin offers two variations: homopolymers and copolymers. Homopolymers showcase elevated crystallinity, resulting in slightly higher density, hardness, strength, and fatigue resistance. On the other hand, copolymers exhibit enhanced thermal stability, improved chemical resistance, and greater ease of processing. For more info, please contact your Polyoxymethylene resin company!

- Good Creep Resistance & High Dimensional Stability even at low temperatures.

- High Strength, Rigidity and Toughness over a wide temperature range.

- Resistant to Chemicals:Good resistance to organic solvents and synthetic detergents...

- Good Resistance to Hydrolysis:Excellent hydrolysis resistance up to 140 °F

- Good Electric Insulation

- Low Water Absorption

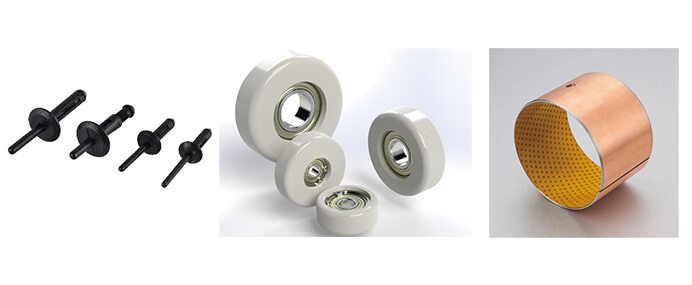

gears, bearings, bushings, rollers, conveyors, window guides, sliding & spring elements, insulators, speaker grilles, fasteners, ski-bindings, zippers, lighters, fuel pump plates, aerosol valves, watch bracelets, medical devices, snap-fits, impellers, furniture components, coils…

| Item | Property | Test Method | Unit | POM-H | POM-C |

|---|---|---|---|---|---|

| Physical | Density | ASTM D 792 | g/cm3 | 1.41 | 1.14 |

| Water Absorption | ASTM D 570 | % | 0.16 | 0.22 | |

| Rockwell Hardness | ASTM D 785 | R scale | 120 | 120 | |

| Mechanical | Tensile Modulus | ASTM D 638 | psi | 4.0 × 105 | 4.5 × 105 |

| Tensile Strength | ASTM D 638 | psi | 11,000 | 9,430 | |

| Flexural Modulus | ASTM D 790 | psi | 4.5 × 105 | 3.9 × 105 | |

| Flexural Strength | ASTM D 790 | psi | 13,000 | 12,000 | |

| Izod Impact | ASTM D 256 | ft-lb/in | 1.0 | 1.0 | |

| Thermal | Heat Deflection Temperature | ASTM D 648 | °C/°F | 121 / 250 | 110 / 230 |

| Linear Coefficient of Expansion | ASTM D 696 | in/in/°F | 4.7 × 10-5 | 5.4 × 10-5 | |

| Flammability | ASTM D 635 | - | HB | HB | |

| Electrical | Electrical Volume Resistivity at 50% RH | ASTM D 257 | Ω/cm | 1015 | 1015 |

| Dielectric Constant | ASTM D 150 | 1 MHz | 3.7 | 3.8 | |

| Dissipation Factor | ASTM D 150 | 1 MHz | 0.005 | 0.005 | |

| Dielectric Strength | ASTM D 149 | V/mm | 33,000 | 40,000 | |