PE, polyethylene, is a non-hygroscopic semi-crystalline thermoplastic with good processability, excellent chemical resistance, low friction coefficient, good fatigue and wear resistance. It is one of the most widely produced plastics in the world. It can be roughly classified into 3 types by density and branching: LDPE, LLDPE, HDPE.

LDPE is a semi-rigid and translucent polymer. It is produced under high pressures and high temperatures. These processes yield a high degree of short and long side-chain branching. Because the branches prevent the polyethylene molecules from packing closely together in hard, stiff, crystalline arrangements, LDPE is a very flexible material.

- Chemical Resistance:Resistance to alcohols, dilute alkalis, and acids.

- Temperature Resistance up to 80°C continuously and 95°C for shorter times.

- High Impact Strength at low temperature.

- Good Weatherability

- Excellent Electrical Insulating Properties

- Low Water Absorption

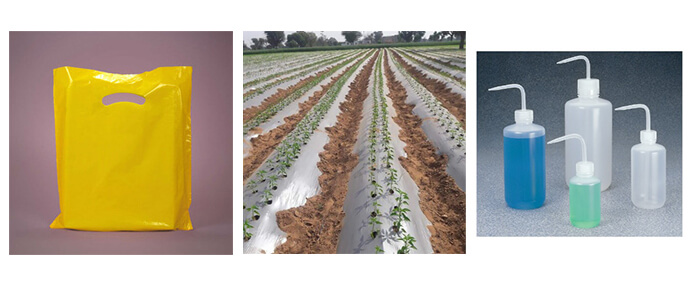

packaging film, agricultural mulch, manufacturing containers, squeeze bottles, toys, tubing, tamper evident, plastic bags for computer components, housewares, laboratory equipment, trash and grocery bags, wire and cable insulation…

LLDPE is structurally similar to LDPE. It is produced by polymerization of ethylene with 1-butene and smaller amounts of 1-hexene and 1-octene, using Ziegler-Natta or metallocene catalysts. Compared to LDPE, its structure has a linear backbone with short uniform branches. Generally, LLDPE has similar properties to LDPE and competes for the same markets. Nowadays, LLDPE has successfully replaced LDPE.

- Very Flexible with high impact strength.

- Good Chemical Resistance:Excellent for mild and strong buffers.

- Good Water Vapor & Alcohol Barrier Properties

general purpose film, roadblocks, plastic barrels, reusable plastic containers, agriculture mulch film, packaging bags, storage tanks, non-food packaging, stretch film, outdoor toys, garment packaging…

HDPE is manufactured at low temperatures and pressures. It is a dense, highly crystalline material of high strength and moderate stiffness because its linear structure and low degree of branching allows the polymer chains to pack closely together. With a melting point more than 20 °C higher than LDPE, it can withstand repeated exposure to 120 °C so that it can be sterilized.

- Excellent Chemical resistance:Resistant to most solvents, alcohols, dilute acids and alkalis…

- Relatively Stiff with useful temperature range (-50°C to +60°C)

- Higher Tensile Strength compared to other forms of PE.

- Good Low Temperature Resistance

- Excellent Electrical Insulating Properties

- Low Water Absorption

bottles for milk and household cleaners, crates, trays, blow-extruded grocery bags, drums, construction film, fabrics, telecommunication cables, industrial bulk containers, ropes, fishing and sport nets, agricultural mulch, ice boxes, garbage containers, jerry cans, pipes and fittings, injection-molded pails, caps, appliance housings, toys…

| Item | Property | Test Method | Unit | LDPE | HDPE |

|---|---|---|---|---|---|

| Physical | Density | ASTM D792 | g/cm3 | 0.92 | 0.96 |

| Water Absorption | ASTM D570 | % | 0.01 | <0.01 | |

| Rockwell Hardness | ASTM D786 | - | 45 | 69 | |

| Mechanical | Tensile Modulus | ASTM D638 | psi | 57,000 | 200,000 |

| Tensile Strength | ASTM D638 | psi | 1,400 | 4,600 | |

| Flexural Modulus | ASTM D790 | psi | 29,000 | 174,000 | |

| Flexural Strength | ASTM D790 | psi | 1,500 | 4,600 | |

| Izod Impact | ASTM D256 | ft-lb/in | 2.38 | 1.3 | |

| Thermal | Vicat Softening Point | ASTM D1525 | °C/°F | - | 125 / 257 |

| Heat Deflection Temperature | ASTM D648 | °C/°F | 48 / 120 | 76 / 170 | |

| Linear Coefficient of Expansion | ASTM D696 | in/in/°F | - | 6×10-5 | |

| Electrical | Electrical Volume Resistivity | ASTM D257 | Ω/cm | > 1015 | > 1015 |

| Dielectric Constant | ASTM D150 | 1 MHz | 2.25- 2.30 | 2.30- 2.35 | |

| Dissipation Factor | ASTM D150 | 1 kHz | 0.0002 | 0.0002 | |

| Dielectric Strength | ASTM D149 | V/mm | 460-700 | 450-500 | |

| Flammability | UL 94 | - | HB | HB< | |