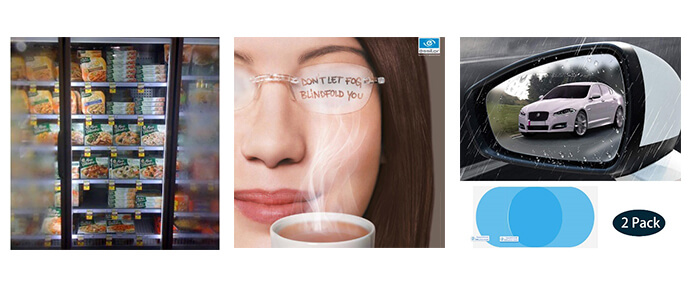

Anti-fog film, also known as anti-condensation film, is a special product designed to prevent fogging on glasses or mirrors. Our anti-fog plastic film is perfect for tough environments like hot and humid conditions, indoor and outdoor work, and climate-controlled areas. Its hydrophilic properties make it effective in a wide range of applications, from everyday use to the automotive, food packaging, and leisure industries.

Prochase anti-fog PET film not only provides excellent anti-fog functionality but also offers exceptional optical clarity and impressive weather durability. Plus, our long-lasting premium AF coating layer ensures clear vision for an extended period, even after multiple washes with water.

- Excellent Surface Hardness

- High Light Transmittance

- Stable Adhesion Performance: No residue

- Pass EN-168 certification

goggles, freezer cases, refrigerators, cameras, windows, face shields, visors, protective clothing, rear mirrors, bathroom mirrors, glasses, masks, and other sports equipment…

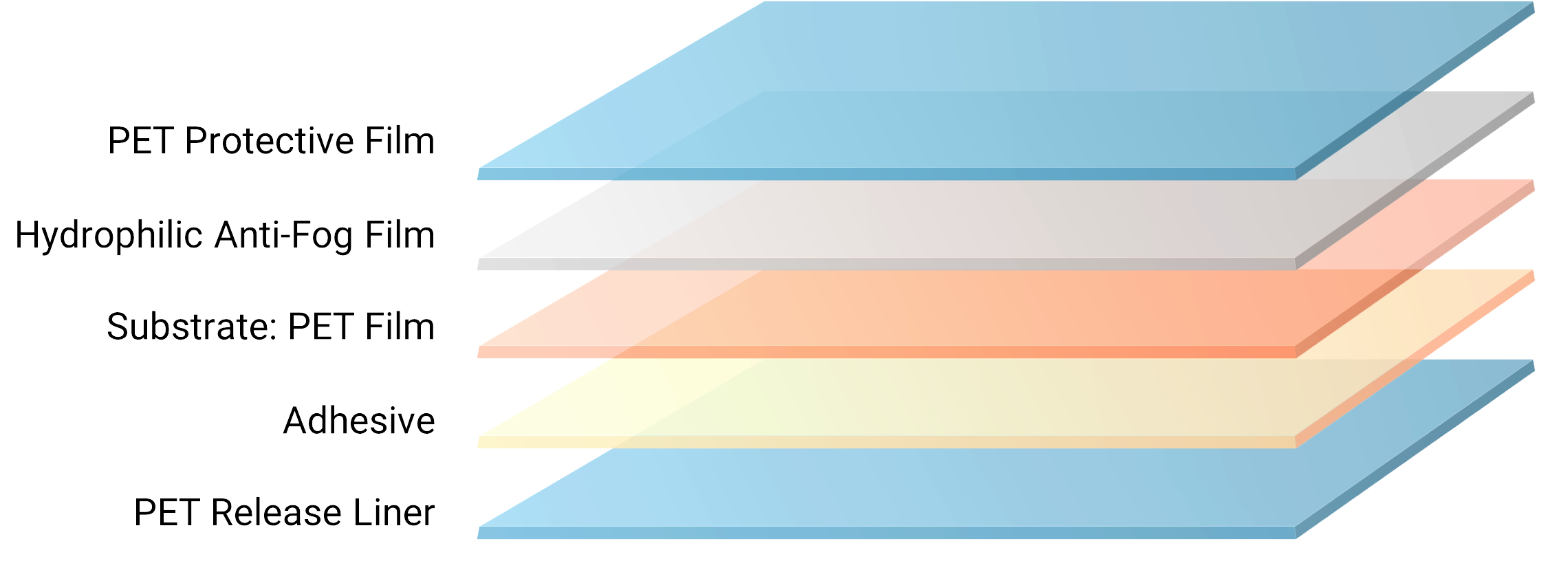

| Substrate Thickness | Adhesive | Hydrophilic Layer |

|---|---|---|

| 50µm | OCA | 20±2 µm |

| 50µm | OCA |

10±2 µm |

| 50µm | PMMA | 20±2 µm |

| 100µm | Silicone | 10±2 µm |