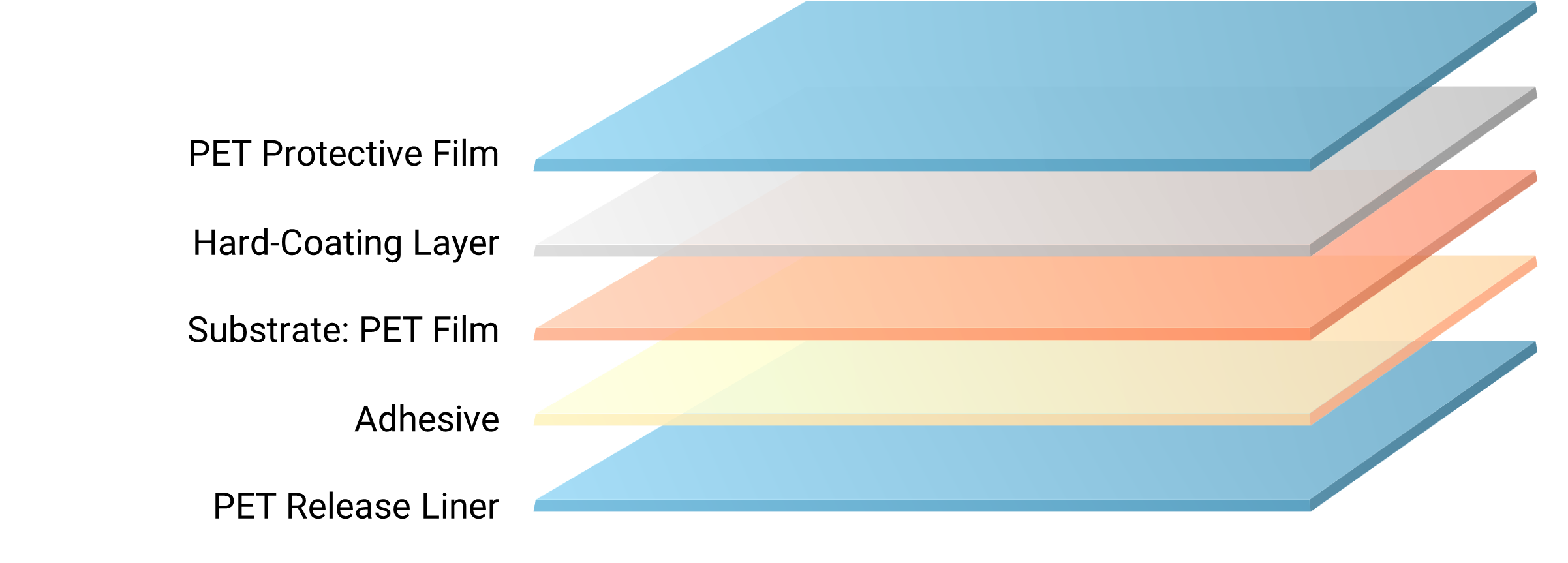

Anti-scratch film, or scratch resistant film, is specifically designed to protect surfaces from daily scratches. It is made of PET film as the base material. The upper layer is treated with durable hard coating, helping to prevent damage in the beginning by serving as a barrier between the surface and external factors responsible for the scratches and abrasion. And the lower layer is coated with silicone pressure-sensitive adhesive, making it highly adhesive and suitable for long-term adhesion. It is extensively utilized in a wide range of applications such as electronic displays, decorative panels, and even in-mold decoration, offering protection for surfaces in high-touch environments.

Prochase clear PET Anti-Scratch Film comes in an array of widths and thicknesses to suit your specific needs. It ensures that surfaces remain safeguarded against scratches, scuffs, and other potential damage.

- Perfect Scratch Resistance

-

High Clarity & Light Transmittance

- Excellent Surface Hardness

- Stable Adhesion Performance. No residue

- Direct Impact Protection

helmet visors, digital camera, face shields, goggles, NB screens, touch displays, mobile phones, TVs, LCD Screens, windows…

| Code | Substrate Thickness | Transmittance | Hardness |

|---|---|---|---|

| - | 75µm | ≧92 |

3H |

| - | 100µm | ≧91 | 3H |

| - | |||

| - | |||